High-Density Polyethylene (HDPE) tubing has become a top choice for many industrial applications due to its exceptional chemical resistance. This versatile material outperforms alternatives like low density polyethylene pipe and black polypropylene pipe in numerous scenarios. Let’s explore the properties that make HDPE tubing so valuable and compare it to other materials like poly pipe for water distribution.

What is Polyethylene Pipe?

Polyethylene pipe, including HDPE, is a plastic tubing made from polyethylene, a versatile polymer used in various industrial and commercial applications. The long chains of ethylene monomers in its molecular structure give polyethylene pipe its unique properties, including chemical resistance, flexibility, and durability.

Types of Polyethylene Pipe

Several types of polyethylene pipe exist, each with distinct properties suited for specific uses:

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Medium-Density Polyethylene (MDPE)

- Cross-linked Polyethylene (PEX)

- Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

HDPE vs. Low Density Polyethylene Pipe

Understanding the differences between HDPE and LDPE is crucial for selecting the right material for your job. Here’s a comparison of the two types of piping:

| Characteristic | HDPE | LDPE |

| Density | 0.941-0.965 g/cm³ (58.7-60.2 lb/ft³) | 0.910-0.940 g/cm³ (56.8-58.7 lb/ft³) |

| Molecular Structure | Linear with minimal branching | Highly branched |

| Crystallinity | 70-80% | 40-50% |

| Tensile Strength | Higher (2,900-5,800 psi) | Lower (1,160-2,900 psi) |

| Chemical Resistance | Excellent | Good |

| Temperature Range | Wider (-76°F to 180°F) | Narrower (-58°F to 122°F) |

| Flexibility | Less flexible | More flexible |

| Permeability | Lower | Higher |

Chemical Resistance Properties of HDPE

HDPE’s chemical resistance is one of its most valuable attributes. The following information is based on data from ISO/TR 10358:2021, which provides the most up-to-date collection of data on combined chemical resistance for thermoplastic materials used in industrial applications.

It’s important to note that the PE considered in this standard corresponds to PE-HD (High-Density Polyethylene), with a minimum density value of 0.935 g/cm³. This includes grades such as PE63, PE80, PE100, PE100-RC, and PE-RT.

The ISO/TR 10358:2021 standard provides a comprehensive list of chemicals and their effects on various thermoplastic materials, including HDPE, over a range of temperatures. While the specific table from the previous version isn’t replicated in the new standard, the general principles of HDPE’s chemical resistance remain similar:

Resistance to Acids

HDPE typically shows excellent resistance to most acids. This includes resistance to common acids like hydrochloric acid, sulfuric acid, and nitric acid at various concentrations and temperatures. However, the exact level of resistance can vary based on concentration and temperature.

Resistance to Bases

HDPE generally demonstrates strong resistance to alkaline solutions. This includes resistance to chemicals like sodium hydroxide and ammonium hydroxide at various concentrations and temperatures.

Resistance to Organic Solvents

HDPE’s resistance to organic solvents can vary. While it often shows good resistance to alcohols like ethanol, it may have limited resistance to some other organic solvents. The exact level of resistance depends on the specific solvent, its concentration, and the temperature.

Resistance to Oxidizing Agents

HDPE typically shows good resistance to oxidizing agents at lower concentrations and temperatures. However, its resistance may decrease at higher concentrations or temperatures.

For specific applications, it’s recommended to consult the full ISO/TR 10358:2021 standard or contact the manufacturer for detailed information on chemical resistance under particular conditions. The standard provides a comprehensive list of chemicals and their effects on HDPE and other thermoplastic materials over a range of temperatures, allowing for more accurate material selection for specific industrial applications.

Factors Affecting Chemical Resistance

Several factors influence HDPE’s chemical resistance:

- Temperature: Higher temperatures often reduce chemical resistance.

- Concentration: Higher concentrations of chemicals typically increase the rate of attack.

- Time of exposure: Longer exposure times may lead to cumulative effects.

- Presence of multiple chemicals: Synergistic effects can occur in mixed chemical environments.

Understanding these factors helps us choose the right HDPE for each job and predict how well it will work with different chemicals.

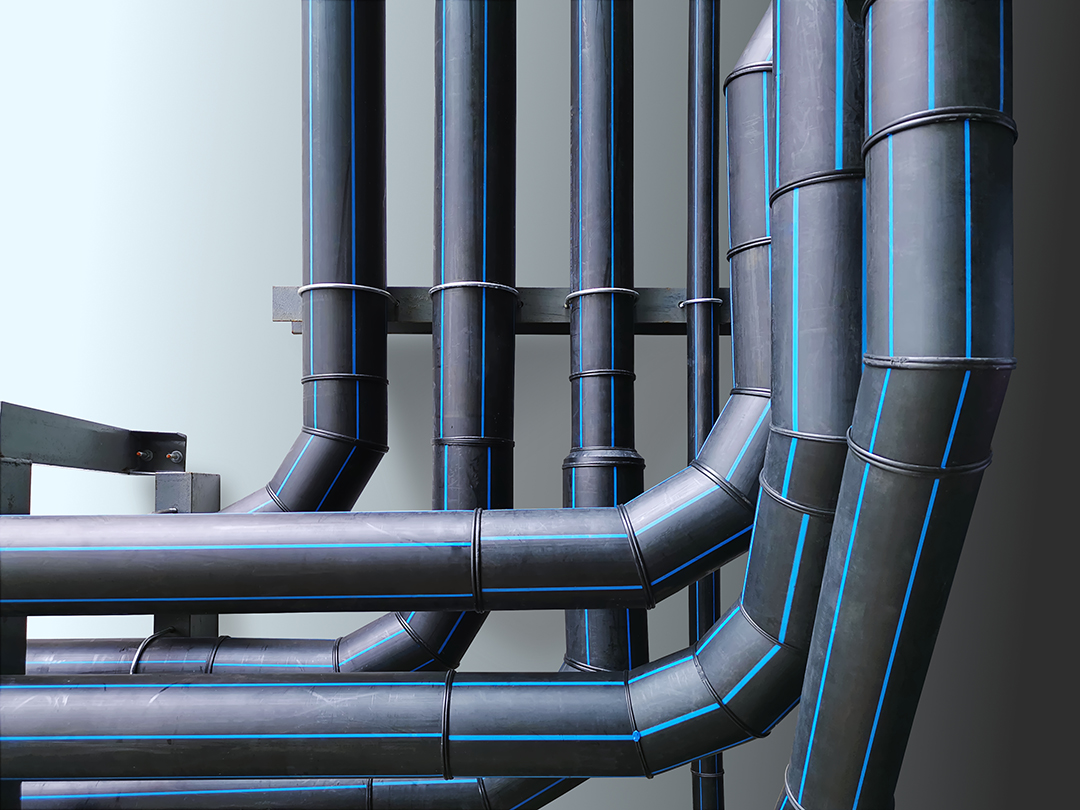

Applications of HDPE Tubing

HDPE tubing’s chemical resistance and durability make it suitable for various industrial applications:

Chemical Processing Industry

HDPE pipe chemical resistance makes it an excellent choice for transporting corrosive chemicals, lining storage tanks, and being used in chemical mixing systems. Its robust ability to withstand a wide range of chemicals and resist corrosion ensures its reliability in even the harshest environments, such as fume exhaust systems where chemical exposure is a constant concern.

Water Treatment Facilities

HDPE tubing is widely used as a poly pipe for water distribution in potable and wastewater treatment systems. Its corrosion resistance and longevity are valuable in desalination plants and sludge handling systems. When equipped with Remote Water Monitoring Systems, HDPE pipes enable real-time tracking of water flow, level, and temperature. This integration of durable HDPE and smart monitoring technology enhances operational efficiency, reduces costs, and improves overall system management in water treatment facilities.

Oil and Gas Industry

HDPE tubing serves in chemical injection lines, produced water handling, and gas gathering systems. Its lightweight nature and corrosion resistance make it suitable for offshore platform piping. HDPE withstands the corrosive nature of extracted water in oil and gas operations.

Food and Beverage Industry

Food-grade HDPE tubing is used in liquid transportation and beverage processing equipment. Its smooth interior and resistance to bacterial growth make it ideal for Clean-in-Place (CIP) systems. In dairy processing, HDPE tubing maintains product purity and resists corrosion from cleaning agents.

These applications demonstrate HDPE tubing’s versatility across industries, where its chemical resistance, durability, and safety features are crucial.

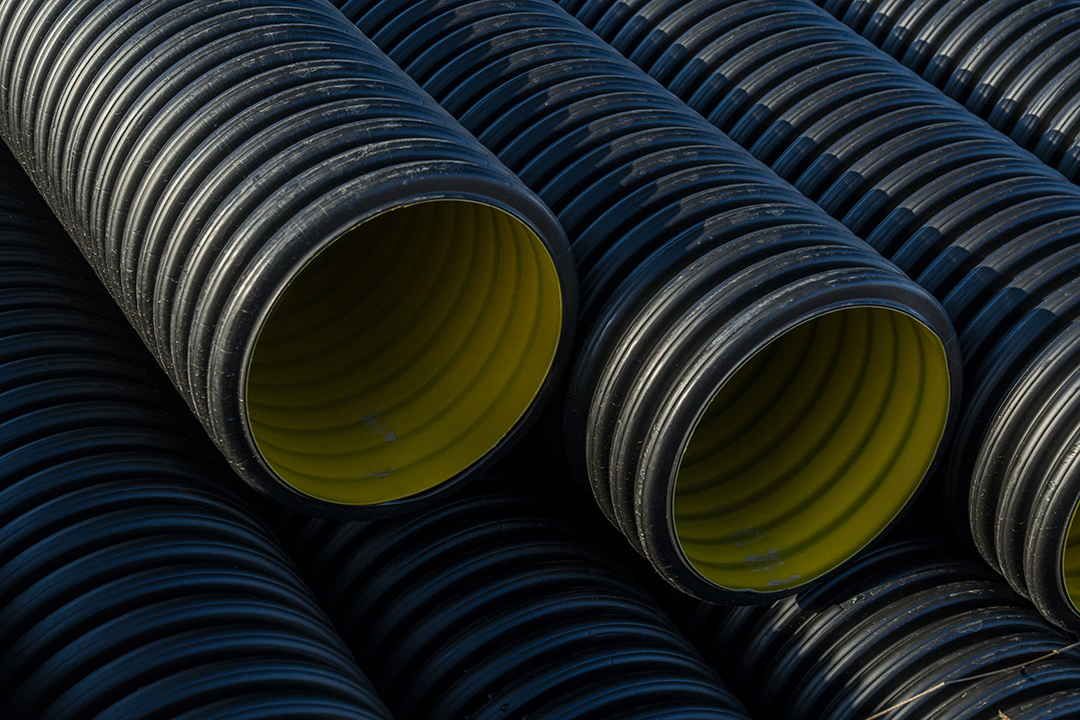

Coastal Resource Group: Industrial HDPE Tubing Solutions

Coastal Resource Group’s HDPE pipes provide excellent chemical resistance for lasting performance.

Coastal Resource Group’s HDPE pipes provide excellent chemical resistance for lasting performance.Coastal Resource Group provides a comprehensive range of industrial supplies, specializing in HDPE tubing. Our inventory includes HDPE pipes, fittings, and related equipment to meet diverse project requirements.

We prioritize efficient service with fast, dependable delivery to keep your projects on schedule. Our team is available 24/7 to address urgent supply needs, ensuring minimal disruption to your operations.

Whether your work involves chemical processing, water treatment, or other industrial applications, we offer the HDPE tubing solutions you need. For expert assistance with your industrial supply requirements, contact us at (281) 549-4132.