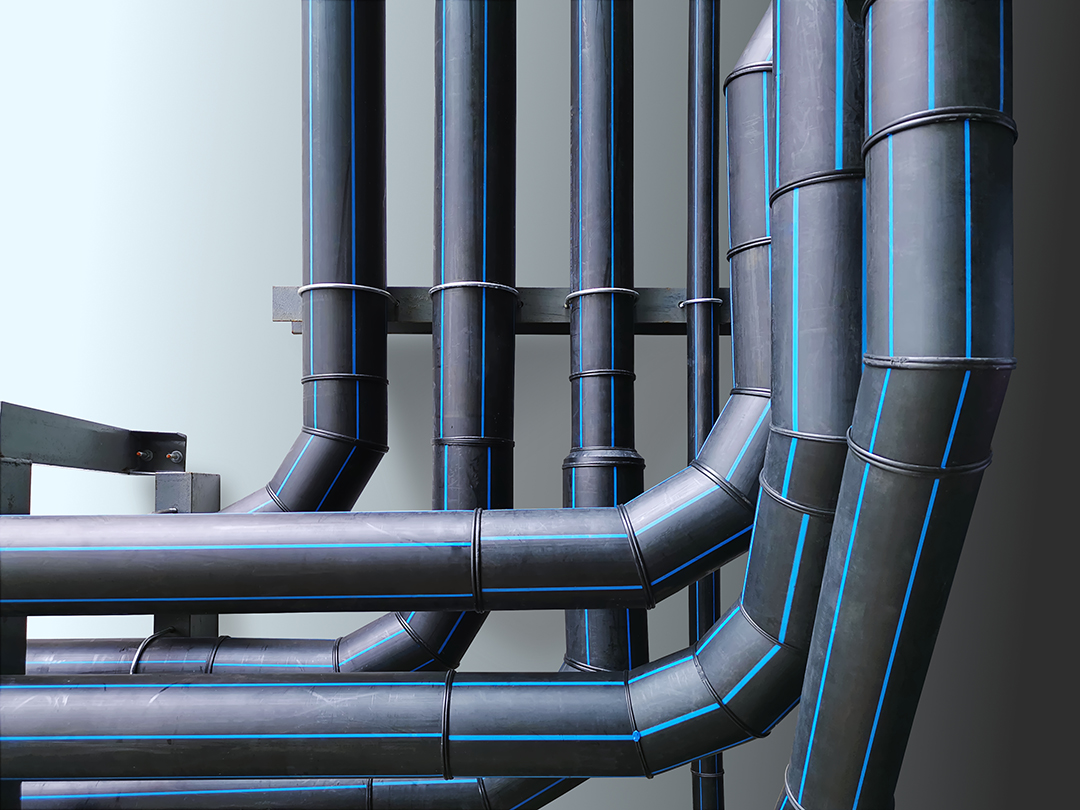

High-density polyethylene (HDPE) pipes are widely used in industrial applications due to their durability, flexibility, and corrosion resistance. For businesses relying on these pipes, understanding the testing procedures that ensure their quality and safety is essential. This article examines the comprehensive testing processes for HDPE pipes, focusing on how these tests guarantee compliance with industry standards and maintain safety in diverse industrial settings.

The Significance of HDPE Pipe Testing

HDPE pipes are vital components in chemical processing, construction, food and beverage, mining, oil & gas, and water treatment industries. Their performance directly impacts system efficiency and safety across these sectors. Rigorous testing verifies that HDPE pipes meet required specifications and can withstand the demands of their intended applications.

HDPE pipe suppliers must adhere to strict quality control measures, ensuring their products meet or exceed industry standards. These tests evaluate material properties, structural integrity, and long-term performance, guaranteeing suitability for each industry’s specific needs.

Density Testing: Foundational Quality Assessment

The density test is a fundamental evaluation of HDPE pipe quality. This test measures the material’s density, which directly correlates with its strength and durability.

The density testing process typically involves:

- Taking samples from the HDPE pipe;

- Using specialized equipment to accurately measure the density; and

- Comparing the results to the standard density of HDPE pipes, which typically ranges from 0.941 to 0.965 g/cm³.

Higher density values generally indicate greater strength and stiffness, which are desirable qualities for pipes used in high-pressure applications. HDPE pipe suppliers must ensure their products fall within the specified density range to meet industry standards.

Tensile Strength: Structural Integrity Evaluation

Tensile strength testing assesses the HDPE pipe’s ability to withstand pulling or stretching forces without failing. This test is critical for determining the pipe’s structural integrity and its capacity to handle the stresses it may encounter during installation and use.

The tensile strength testing process includes:

- Preparing standardized samples from the HDPE pipe;

- Subjecting these samples to increasing loads using specialized equipment;

- Measuring and recording key parameters such as yield strength, ultimate tensile strength, and elongation at break; and

- Analyzing the results to determine the pipe’s suitability for specific applications.

These parameters help engineers and end-users select the appropriate HDPE pipe based on the expected stress levels in their intended use.

Hydrostatic Pressure Testing: Leak Resistance Assessment

The hydrostatic pressure test is a crucial evaluation of HDPE pipes’ ability to withstand internal pressure without leaking or failing. This test simulates the conditions the pipe will experience in real-world applications, particularly in water and gas distribution systems.

The hydrostatic pressure testing procedure involves:

- Filling the HDPE pipe with water;

- Pressurizing the pipe to a level exceeding its normal operating pressure;

- Monitoring the pipe for a specified period to detect any leaks or signs of failure; and

- Evaluating the results to ensure the pipe maintains its integrity under pressure.

HDPE pipe diameters and pressure pipe dimensions play a significant role in determining the appropriate test pressures and durations. Larger diameter pipes and those designed for higher pressure ratings typically undergo more rigorous hydrostatic testing to ensure their reliability in demanding applications.

Oxidation Induction Time (OIT) Test: Long-Term Durability Evaluation

The Oxidation Induction Time (OIT) test assesses the HDPE pipe’s resistance to oxidation, which is an important factor in determining its long-term performance and lifespan. Oxidation can lead to degradation of the pipe material, potentially causing premature failure.

The OIT testing process includes:

- Preparing a small sample of the HDPE pipe material;

- Heating the sample in an oxygen-rich environment;

- Measuring the time it takes for the sample to begin oxidizing; and

- Recording this time as the OIT value.

A higher OIT value indicates better resistance to oxidation and, consequently, a longer expected service life for the pipe. HDPE pipe suppliers must ensure their products meet or exceed the minimum OIT requirements specified by industry standards.

Melt Flow Rate (MFR) Test: Processing Characteristics Assessment

The Melt Flow Rate (MFR) test evaluates the flow properties of the HDPE material used in pipe production. This test provides valuable information about the material’s processability and its suitability for various manufacturing techniques.

The MFR testing procedure involves:

- Heating a sample of the HDPE material to its melting point;

- Extruding the melted material through a standardized die under a specified load;

- Measuring the amount of material that flows through the die in a given time; and

- Expressing the result as the MFR value, typically in grams per 10 minutes.

The MFR test results help HDPE pipe manufacturers optimize their production processes and ensure consistent quality across different batches of pipes. It also allows end-users to select pipes with appropriate flow characteristics for their specific applications, particularly in fusion joining processes.

Coastal Resource Group Delivers Reliable HDPE Pipe Solutions

Coastal Resource Group is a leading industrial supply company offering a comprehensive range of HDPE pipes, fittings, and equipment that meet or exceed industry standards. Our experts can guide you in selecting the right pipes for your specific needs across various industrial applications.

We provide a wide selection of HDPE pipes with various diameters and pressure ratings, all backed by rigorous testing procedures. Our fast delivery and 24/7 availability ensure your industrial supply needs are met efficiently, keeping your operations running smoothly.

For reliable HDPE pipe solutions and expert guidance, choose Coastal Resource Group as your one-stop shop. Contact us today to experience the difference of working with a dedicated industrial supply partner.