Infrastructure projects demand meticulous material selection, particularly for piping systems. In recent years, high-density polyethylene (HDPE) pipes have emerged as an innovative option for many applications Their durability, flexibility, and potential for cost savings have attracted the attention of engineers and project managers across various sectors. The cost-efficiency of HDPE tubing in long-term projects presents a compelling case for its increased adoption in modern infrastructure development.

Overview of HDPE Pipes

HDPE pipes are made from thermoplastic polymer materials. Their unique properties make them suitable for various applications. These pipes are known for being:

- Resistant to both corrosion and chemicals;

- Flexible and lightweight;

- Having a long service life;

- The ability to withstand environmental stresses; and

- Being able to transport fluids efficiently.

HDPE pipes are used in municipal water systems, industrial applications, and drainage projects.

Initial Costs: HDPE vs. Steel Pipes

HDPE pipes often have higher upfront costs than steel pipes but offer long-term advantages. HDPE, a flexible thermoplastic, excels in high-pressure pipelines for hazardous waste, stormwater, and gases across various sectors. On the other hand, steel pipes—which are rigid and versatile—are common in water supply lines and structural applications.

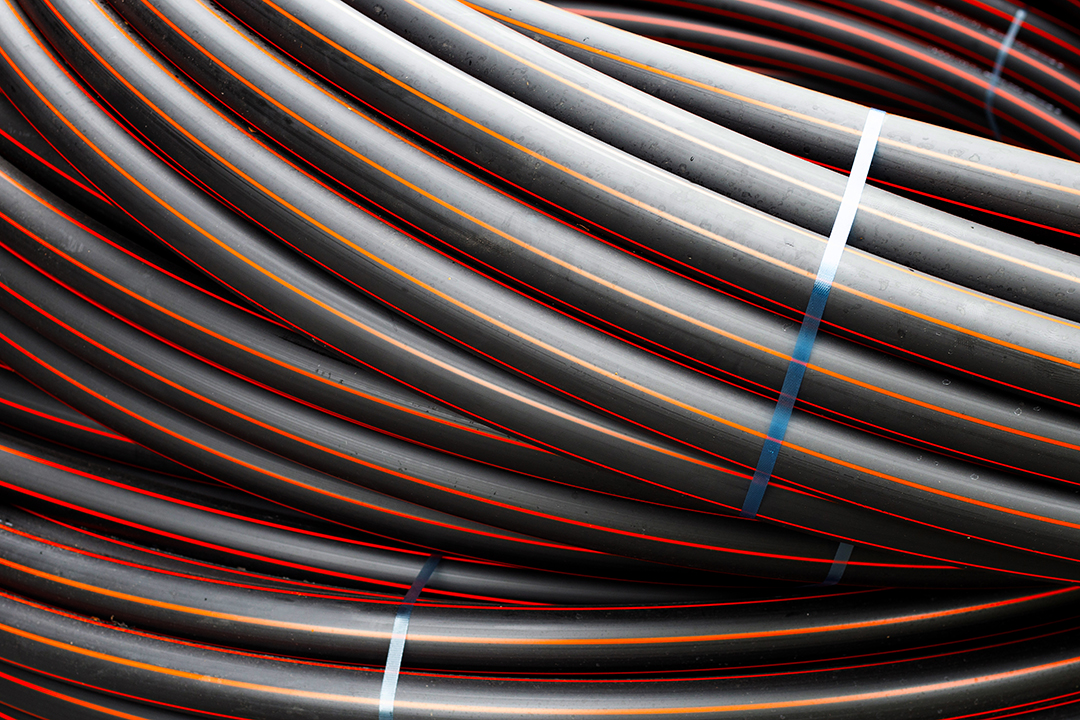

HDPE pipes are lightweight with flexible coiled lengths, making their transportation and installation easier compared to heavier steel pipes. HDPE resists corrosion and chemicals, protecting internal materials, while steel pipes eventually corrode and can contaminate the very contents that they are carrying.

HDPE pipes last 50 to 100 years without external degradation, surpassing the 40 to 50-year lifespan of galvanized steel pipes. Despite their higher initial price, HDPE pipes have proven to be more economical in the long term. Their durability reduces replacement and maintenance costs, especially in sewer systems where they are used to replace easily damaged concrete or steel pipes.

Installation Costs and Efficiency

HDPE pipes offer significant economic benefits during installation. Their lightweight design makes transportation and handling easier, directly reducing labor costs. The flexibility of HDPE pipes allows for easier placement in open-cut scenarios and makes them easily adaptable to changing ground conditions, further streamlining the installation process.

HDPE’s efficiency extends to large-scale projects. For instance, a water pipeline project for the San Antonio Water System, spanning 122,149 feet, demonstrated HDPE’s installation advantages. Crews fused long pipe sections above ground ahead of installation, resulting in an accelerated project timeline and lower overall costs.

The economic impact of HDPE tubing is substantial. In a comparative case from India, an HDPE pipeline project cost $129,382 USD, while an equivalent mild steel pipeline would have cost nearly $299,000 USD—more than double the cost of HDPE tubing. This cost difference doesn’t account for the additional expenses steel pipes incur for corrosion-resistant coatings and future maintenance.

By reducing installation time, HDPE pipes minimize labor costs and community disruption during construction. This quicker turnaround leads to faster project completion and earlier return on investment, particularly beneficial for large-scale infrastructure projects.

Long-Term Performance and Maintenance Costs

HDPE tubing’s true cost-efficiency becomes clear when considering long-term performance and maintenance costs. HDPE pipes are durable and resist various forms of degradation. This leads to lower maintenance requirements and a longer service life. They resist corrosion and chemical attack. They can withstand ground movement and settling. Their smooth interior surface resists buildup. HDPE pipes have a lower likelihood of leaks or joint failures. And, they have an expected service life of 50-100 years.

These characteristics result in reduced maintenance needs. They also lead to enhanced efficiency and reliability in midstream applications. While the initial cost of HDPE pipe may be higher, the long-term savings often outweigh this.

Case Study: HDPE Pipe in Critical Infrastructure

Real-world examples demonstrate the effectiveness of HDPE pipes in critical infrastructure. A notable case in Fort Lauderdale, Florida, showcased how HDPE technology solved a major infrastructure crisis. This case study highlights both the immediate and long-term benefits of HDPE pipes, which are equally applicable to other sectors like hospitals that require reliable, corrosion-resistant infrastructure.

Key details of the case study:

| Project | Challenge | Solution | Benefits |

| Fort Lauderdale Sewer Line Replacement | – 200 million gallon sewage spill

– Urgent need for replacement |

HDPE pipeline installed via directional drilling | – Rapid installation

– Leak resistance – Long-term durability – Cost-effective for urgent and long-term use |

This HDPE solution addressed both immediate and long-term needs, demonstrating its potential for maintaining essential services in various critical infrastructure settings.

Factors Affecting HDPE Pipe Prices

Understanding what influences HDPE pipe prices can help project managers make informed decisions when weighing piping options. Several key factors can include pricing, including:

- Raw material costs;

- Pipe specifications and manufacturing processes;

- Order volume (larger orders often qualify for discounts);

- Transportation costs; and

- Market competition in different regions.

Comparing HDPE Pipe Costs Across Different Applications

The cost-efficiency of HDPE pipes varies across different applications in the oil and gas industry. While initial costs may be higher in some cases, the long-term benefits often outweigh this. For example, in midstream operations, HDPE tubing offers significant advantages such as corrosion resistance and flexibility, ideal for challenging terrains.

In industrial processes, HDPE pipes excel in chemical and abrasion resistance, making them suitable for various downstream applications including water and wastewater management. These characteristics contribute to enhanced efficiency and reliability in oil and gas operations.

The initial investment in HDPE pipes is offset by reduced maintenance costs, longer lifespan, and improved operational performance. This makes HDPE a cost-effective choice for numerous oil and gas applications, from gathering lines to processing plants.

Future Trends in HDPE Pipe Technology and Pricing

Several trends are likely to impact future HDPE pipe costs and applications. Improved manufacturing processes may lead to price reductions. The development of higher-performance HDPE resins could open up new specialized applications. Increased adoption of HDPE pipes may lead to economies of scale. This could potentially lower costs. A growing focus on sustainability is driving innovations in recycling and reuse. Advancements in installation techniques could further reduce labor costs. These trends suggest that HDPE tubing’s cost-efficiency in long-term projects is likely to improve further in the coming years.

Choosing Coastal Resource Group for Your HDPE Pipe Needs

Coastal Resource Group offers a comprehensive range of HDPE pipes and fittings. We have expertise in industrial and oilfield supply, and years of customer service that include:

- Competitive pricing on high-quality HDPE pipes;

- Fast delivery to keep your project on schedule;

- Expert advice on selecting the right HDPE products;

- 24/7 availability for supply emergencies; and

- Comprehensive inventory covering various pipe sizes and specifications.

By choosing Coastal Resource Group, you ensure cost-efficient solutions for your infrastructure projects. Our team can help you balance upfront costs with long-term performance and maintenance savings. Contact us today to discuss your HDPE pipe requirements. Let us show you how we can contribute to the success of your long-term infrastructure projects.