Industrial Bolts For The Oil & Gas

Industrial Bolts For The Wastewater & Water Industry

Industrial Bolts For The Agriculture & Irrigation

Industrial Bolts For The Chemical Processing Industry

Industrial Bolts For The Manufacturing & Processing

Industrial Bolts For The Oil & Gas

Oil and Gas Industry Applications and Uses for Flange Bolts

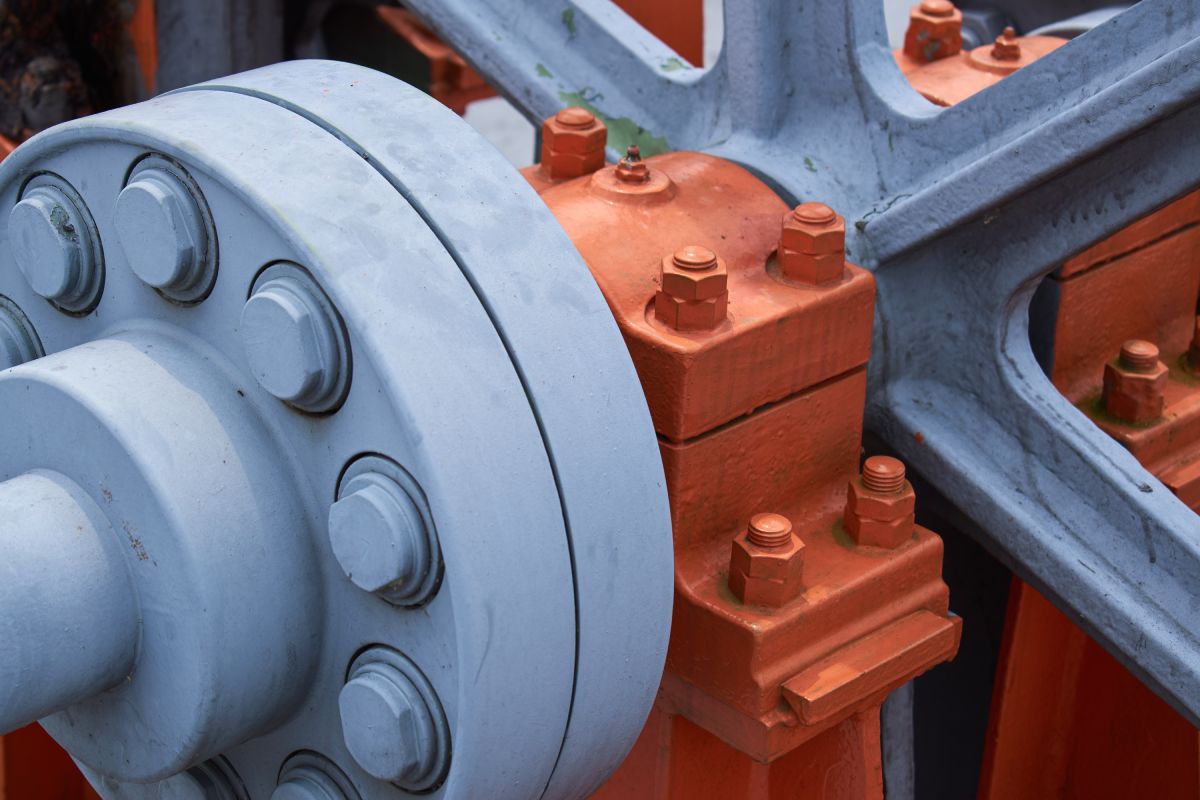

Flange bolts play a crucial role in the oil and gas industry, ensuring the secure connection of pipes, valves, and other critical equipment.In applications like pipeline flanges, heat exchangers, and pressure vessels, flange bolts help maintain the structural integrity of systems that transport and process oil and gas, minimizing the risk of leaks or failures that could result in costly downtime or environmental damage. Their durability and reliability are essential for the safe and efficient operation of oil and gas facilities.

Industrial Bolts For The Wastewater & Water Industry

Wastewater & Water Industry Applications and Uses for Flange Bolts

Flange bolts are essential in the wastewater and water industries, where they ensure the secure connection of pipes, pumps, and valves in water treatment facilities and distribution systems. These bolts are used to fasten flanges on pipelines, tanks, and filtration systems, maintaining the integrity of equipment that handles large volumes of water. In both wastewater management and potable water systems, flange bolts play a critical role in preventing leaks and ensuring efficient flow, even under fluctuating pressure conditions. Their corrosion-resistant properties make them ideal for use in environments exposed to moisture, chemicals, and varying temperatures, ensuring long-term reliability in water infrastructure.

Industrial Bolts For The Agriculture & Irrigation

Agriculture & Irrigation Applications and Uses for Flange Bolts

Flange bolts play a critical role in agriculture and irrigation systems by providing secure and durable connections in piping networks. These bolts are commonly used to fasten flanged fittings, ensuring a tight seal between pipes that transport water, fertilizers, or other essential fluids across farmland. In irrigation systems, flange bolts help maintain the integrity of the piping under pressure, preventing leaks and ensuring consistent water flow to crops. Their corrosion-resistant materials, such as stainless steel, make them ideal for use in outdoor environments where moisture and soil exposure are constant. Reliable and easy to install, flange bolts are essential components in both small-scale and large-scale agricultural operations, facilitating efficient irrigation and resource management.

Industrial Bolts For The Chemical Processing Industry

Chemical Processing Industry Applications and Uses for Flange Bolts

In the chemical processing industry, flange bolts play a critical role in ensuring secure, leak-free connections in piping systems that transport hazardous and corrosive chemicals. These bolts are used to fasten flanges, which join sections of pipe or connect pipes to valves, pumps, and other equipment. Due to the aggressive nature of many chemicals, flange bolts are often made from corrosion-resistant materials like stainless steel or coated with protective finishes. Their precise torque application is essential to prevent leaks, maintain system integrity, and ensure safety in high-pressure and high-temperature environments. Flange bolts are key components in industries such as petrochemicals, pharmaceuticals, and food processing, where the safe and efficient transport of fluids is paramount.

Industrial Bolts For The Manufacturing & Processing

Manufacturing & Processing Applications and Uses for Flange Bolts

In the manufacturing and processing industries, flange bolts are essential for creating strong, reliable connections between piping and equipment, such as pumps, compressors, and valves. These bolts secure flanges, which are used to join pipe sections or connect machinery, ensuring fluid, gas, or air flows smoothly through production systems. Flange bolts are commonly used in high-pressure and high-temperature environments, making them crucial in industries like oil and gas, food processing, and pharmaceuticals. Manufactured from materials like carbon steel or stainless steel, these bolts withstand corrosive substances and extreme conditions. Their ability to maintain tight seals reduces downtime, enhances safety, and ensures efficient operation across various industrial applications.

Industrial flange bolts, including

Industrial flange bolts, including  Flange bolts play a crucial role in the oil and gas industry, ensuring the secure connection of pipes, valves, and other critical equipment.In applications like pipeline flanges, heat exchangers, and pressure vessels, flange bolts help maintain the structural integrity of systems that transport and process oil and gas, minimizing the risk of leaks or failures that could result in costly downtime or environmental damage. Their durability and reliability are essential for the safe and efficient operation of oil and gas facilities.

Flange bolts play a crucial role in the oil and gas industry, ensuring the secure connection of pipes, valves, and other critical equipment.In applications like pipeline flanges, heat exchangers, and pressure vessels, flange bolts help maintain the structural integrity of systems that transport and process oil and gas, minimizing the risk of leaks or failures that could result in costly downtime or environmental damage. Their durability and reliability are essential for the safe and efficient operation of oil and gas facilities.

Flange bolts are essential in the wastewater and water industries, where they ensure the secure connection of pipes, pumps, and valves in water treatment facilities and distribution systems. These bolts are used to fasten flanges on pipelines, tanks, and filtration systems, maintaining the integrity of equipment that handles large volumes of water. In both wastewater management and potable water systems, flange bolts play a critical role in preventing leaks and ensuring efficient flow, even under fluctuating pressure conditions. Their corrosion-resistant properties make them ideal for use in environments exposed to moisture, chemicals, and varying temperatures, ensuring long-term reliability in water infrastructure.

Flange bolts are essential in the wastewater and water industries, where they ensure the secure connection of pipes, pumps, and valves in water treatment facilities and distribution systems. These bolts are used to fasten flanges on pipelines, tanks, and filtration systems, maintaining the integrity of equipment that handles large volumes of water. In both wastewater management and potable water systems, flange bolts play a critical role in preventing leaks and ensuring efficient flow, even under fluctuating pressure conditions. Their corrosion-resistant properties make them ideal for use in environments exposed to moisture, chemicals, and varying temperatures, ensuring long-term reliability in water infrastructure.

Flange bolts play a critical role in agriculture and irrigation systems by providing secure and durable connections in piping networks. These bolts are commonly used to fasten flanged fittings, ensuring a tight seal between pipes that transport water, fertilizers, or other essential fluids across farmland. In irrigation systems, flange bolts help maintain the integrity of the piping under pressure, preventing leaks and ensuring consistent water flow to crops. Their corrosion-resistant materials, such as stainless steel, make them ideal for use in outdoor environments where moisture and soil exposure are constant. Reliable and easy to install, flange bolts are essential components in both small-scale and large-scale agricultural operations, facilitating efficient irrigation and resource management.

Flange bolts play a critical role in agriculture and irrigation systems by providing secure and durable connections in piping networks. These bolts are commonly used to fasten flanged fittings, ensuring a tight seal between pipes that transport water, fertilizers, or other essential fluids across farmland. In irrigation systems, flange bolts help maintain the integrity of the piping under pressure, preventing leaks and ensuring consistent water flow to crops. Their corrosion-resistant materials, such as stainless steel, make them ideal for use in outdoor environments where moisture and soil exposure are constant. Reliable and easy to install, flange bolts are essential components in both small-scale and large-scale agricultural operations, facilitating efficient irrigation and resource management.

In the chemical processing industry, flange bolts play a critical role in ensuring secure, leak-free connections in piping systems that transport hazardous and corrosive chemicals. These bolts are used to fasten flanges, which join sections of pipe or connect pipes to valves, pumps, and other equipment. Due to the aggressive nature of many chemicals, flange bolts are often made from corrosion-resistant materials like stainless steel or coated with protective finishes. Their precise torque application is essential to prevent leaks, maintain system integrity, and ensure safety in high-pressure and high-temperature environments. Flange bolts are key components in industries such as petrochemicals, pharmaceuticals, and food processing, where the safe and efficient transport of fluids is paramount.

In the chemical processing industry, flange bolts play a critical role in ensuring secure, leak-free connections in piping systems that transport hazardous and corrosive chemicals. These bolts are used to fasten flanges, which join sections of pipe or connect pipes to valves, pumps, and other equipment. Due to the aggressive nature of many chemicals, flange bolts are often made from corrosion-resistant materials like stainless steel or coated with protective finishes. Their precise torque application is essential to prevent leaks, maintain system integrity, and ensure safety in high-pressure and high-temperature environments. Flange bolts are key components in industries such as petrochemicals, pharmaceuticals, and food processing, where the safe and efficient transport of fluids is paramount.

In the manufacturing and processing industries, flange bolts are essential for creating strong, reliable connections between piping and equipment, such as pumps, compressors, and valves. These bolts secure flanges, which are used to join pipe sections or connect machinery, ensuring fluid, gas, or air flows smoothly through production systems. Flange bolts are commonly used in high-pressure and high-temperature environments, making them crucial in industries like oil and gas, food processing, and pharmaceuticals. Manufactured from materials like carbon steel or stainless steel, these bolts withstand corrosive substances and extreme conditions. Their ability to maintain tight seals reduces downtime, enhances safety, and ensures efficient operation across various industrial applications.

In the manufacturing and processing industries, flange bolts are essential for creating strong, reliable connections between piping and equipment, such as pumps, compressors, and valves. These bolts secure flanges, which are used to join pipe sections or connect machinery, ensuring fluid, gas, or air flows smoothly through production systems. Flange bolts are commonly used in high-pressure and high-temperature environments, making them crucial in industries like oil and gas, food processing, and pharmaceuticals. Manufactured from materials like carbon steel or stainless steel, these bolts withstand corrosive substances and extreme conditions. Their ability to maintain tight seals reduces downtime, enhances safety, and ensures efficient operation across various industrial applications.